Health, Safety & CDM Requirements

Client: Various

Role: Safety Management & CDM Requirements

Site Safety Management

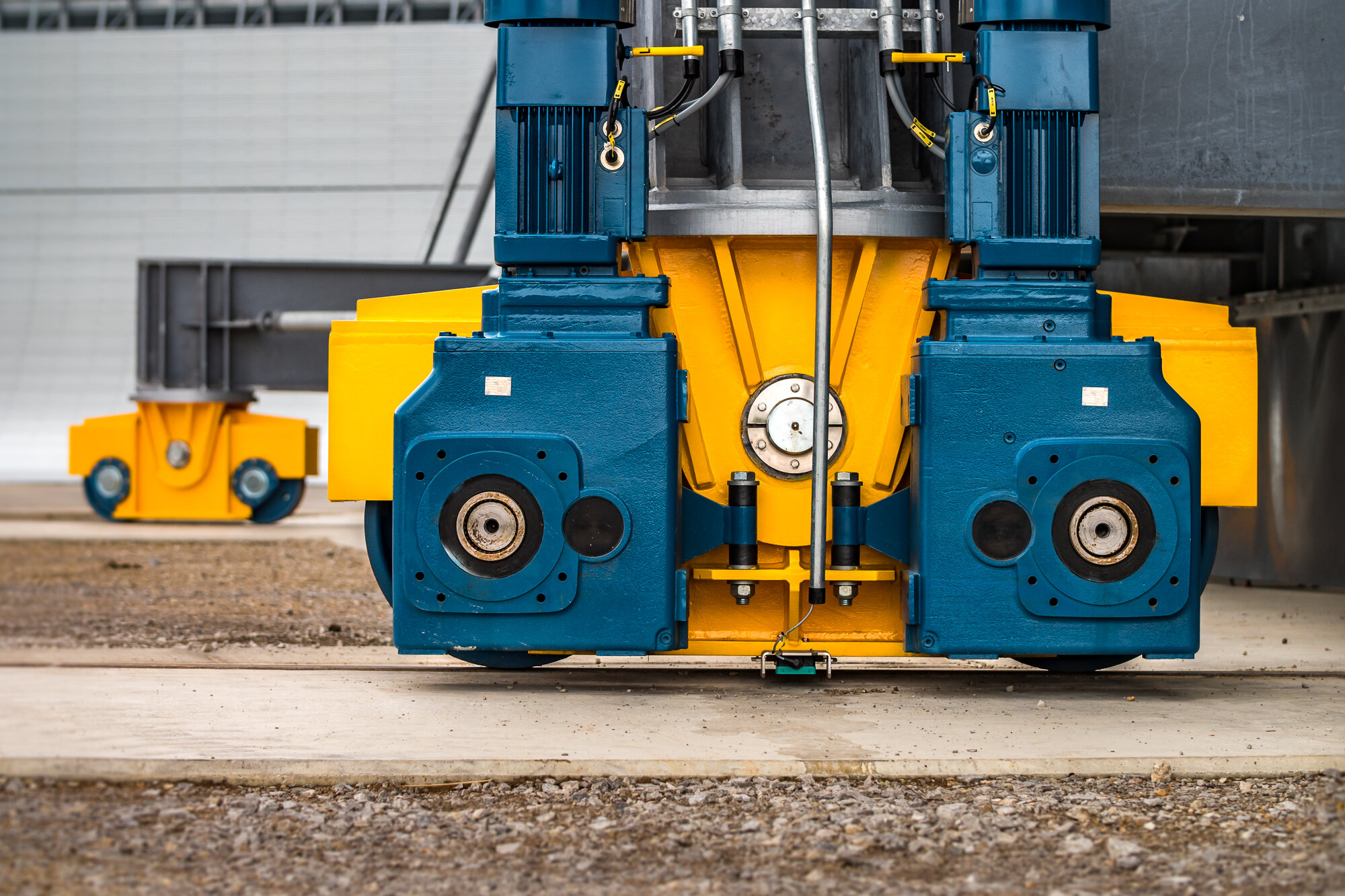

BDPSP worked with BDI to complete the health and safety management for a maintenance inspection of a facility in the UK. BDI are world leaders in the development and installation of blast structures and engine running bays used in airports all over the world. This maintenance visit saw a mechanical check of key structural components, gear boxes and motors and was completed by a team from mainland Europe, and a fixed wiring electrical inspection by a UK team.

BDPSP developed an onsite safety procedure for operating during covid restrictions, a site induction (translated in to Czech) and reviewed all of the risk assessments and method statements before submission to the Client. Whilst works were progressing, we were on site, monitoring safety and reviewing and auditing works in progress. We assisted with checking equipment certification and test certificates for electrical inspection works. The visit was completed on time, with no health and safety issues.

Induction Processes

BDPSP worked with GTLC at RAF Marham to develop a clear induction with a voice over that would be used to ensure all personnel had a basic level of understanding of the safety requirements for the project. Traditionally, inductions for complex projects can take up the time of safety personnel, until it becomes an unwieldy task and takes away from the day to day management of safety, or worse, does not get delivered correctly.

The induction utilised a powerpoint presentation so it could easily be amended, with voice over software to issue the message it was conveying. It enabled a consistent and simple to understand message to be given to every single person that entered the site. It was available on a USB so that it could be delivered by the safety manager and other key staff, who whilst the induction was being completed, used the time to check training records and ensure paperwork was completed correctly. This saved time and resource, whilst maintaining a high standard of information communicated to new starters.

Noise Monitoring

BDPSP has worked at a UK airport to assist with monitoring of project specific noise.

The project included cutting, ratcheting and grinding of metal with relatively close proximity to local households.

We utilised a handheld noise monitor and took readings on site and at fixed points from the site agreed with the Client. This was repeated twice a week and more during noise activities to build a picture of the impact from the project.

The information gathered through our noise monitoring activities was used to plan construction activities on a weekly basis and to provide information to the Client on the impact to its neighbours.

CDM Co-ordination

BDPSP offered project support to a UK airport to identify specific CDM items to incorporate into its pre-construction information.

BDPSP visited the site and reviewed the scope of works against the conditions and surveys that had been completed. This was utilised to enable procurement of the project.

All of our staff based on-site during projects have received full CDM training and understand the importance of UK legislation and the impact this can have on construction projects.

"BDPSP gave us the reassurance we needed to complete our annual maintenance works in full compliance with safety requirements. The service provided was pro-active, professional and friendly, ensuring that we had everything in place, and therefore avoiding any site delays, and giving our Client the confidence that we were working safely."

Nick Smith

BLAST DEFLECTORS, INC.